|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

Injection Pump Shut-off

I have a 1993 300 SD that the Stop fuel shut-off lever sticks at the closed position and will not pop back up. Or will not shut off the engine unless the lever is mover 1/8 inch more by hand. There is good vacuum. The lever does move easily about 75 degrees when the key is turned off. When moving the lever by hand counter clockwise from the 12 o'clock (Run) to 10 o'clock (Stop) it is smooth. There is something binding from the 10 o'clock to the 9 o'clock. By moving the lever just so slightly down another 1/8 inch will stop the engine.

Thanks Dean Three six zero three zero one twenty fifty-five |

|

#2

|

||||

|

||||

|

Have you checked out the linkages on the side of the IP? Are they catching on anything?

__________________

72% 1992 FJ80 + 17% 1983 OM617 + 10% 85/87/92 4Runner + *Eclipse/GMC = 100% Truck (*<1%) Build Thread: http://forum.ih8mud.com/threads/a-humble-fj80-om617-r151f-swap.759554/ |

|

#3

|

|||

|

|||

|

Linkage is good.

|

|

#4

|

||||

|

||||

|

Where are you located, and is this a new symptom or a new car?

Can you move the shutoff lever shaft in/out (axial play) of the pump? If so, it is possible that someone has replaced the seal and did not install the snap-ring and spacer before installing the shutoff lever. If all is well externally, remove the shutoff actuator on top (need to remove the intake plenum and ALDA first), look down to see if the arm that is inside of the pump has been bent and is binding with other linkage. Does it still bind with the (vacuum) shutoff actuator removed? If the shutoff lever seal was serviced incorrectly, it is possible that someone has bent it internally (removing threaded bushing instead of snap-ring).

__________________

Gone to the dark side - Jeff |

|

#5

|

|||

|

|||

|

Yes, there is in/out play on the axial of the shut off lever. Shut off was working fine. I replaced the delivery seals and a week later the shut off problem started and has gotten worse over the past few weeks. I was hoping for an easy fix without taking the intake manifold off. Is it possible to pull out the shut off shaft by unscrewing the seal nut?

|

|

#6

|

|||

|

|||

|

I located near Port Townsend, WA

|

|

#7

|

||||

|

||||

|

The shutoff shaft is connected to a stamped steel part inside of the IP, not sure how it's connected whether it's welded or removable but IIRC it is permanently connected (swedged, welded, other?). In this case replacement will require it to go in, not out. If you pull the "seal nut" (bushing), it does not give enough clearance for the stamped arm inside to come out. However, this bushing is held in place with some loc-tite, and you will need to remove the lock-ring before turning this bushing, and ensure that you are not putting any axial load on the shaft while you remove the bushing or you will bend/damage the stamped arm inside and possibly other linkage parts.

Check to see if there is a snap-ring and spacer/washer installed on the shaft against the bushing, there is also an O-ring just inside this bushing. If all are not present then this is your problem. Also, slide the shaft outward and see if it still binds. I am curious how the shaft is attached to the stamping inside the pump, might pull the shutoff actuator off of my spare today just to find out, will let you know if I do.

__________________

Gone to the dark side - Jeff |

|

#8

|

|||

|

|||

|

Thanks. Will have have a closer look. Could you send me your email address so I could send you some photos? Deansj35@gmail.com

Three six zero three zero one twenty fifty five |

|

#9

|

||||

|

||||

|

Will do.

The most likely culprit is the vacuum shutoff actuator, 2nd most likely is improperly serviced seal on the shaft. If the shaft seal is installed properly with the snap-ring and spacer then you will most likely need to un-install the shutoff actuator to determine whether it binds without, I replaced this recently in my '93 and IIRC I couldn't do it without removal of the intake to get the ALDA off.

__________________

Gone to the dark side - Jeff |

|

#10

|

||||

|

||||

|

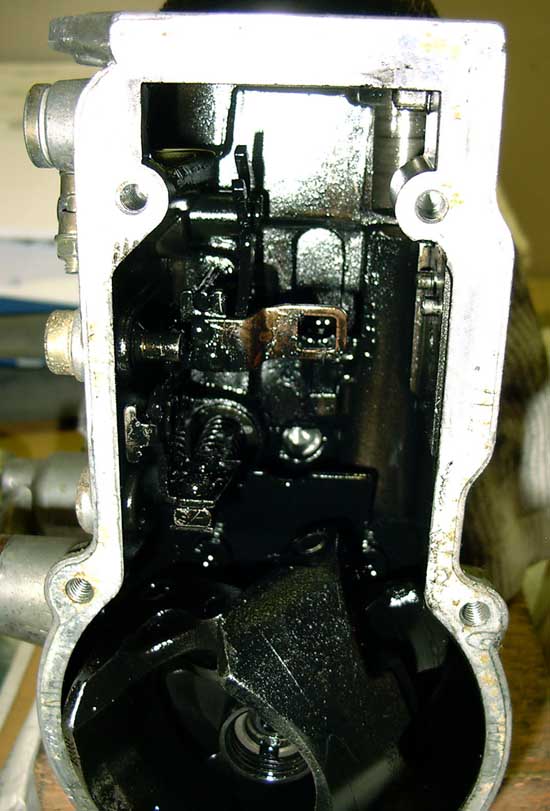

Many wish gsxr invested in a can of brake parts cleaner before taking these pictures:

Sixto 83 300SD |

|

#11

|

||||

|

||||

|

#12

|

|||

|

|||

|

Thanks so much for all the great help. Got the car back running at 12:30 a.m. this morning. It was just as you said. The vacuum shutoff actuator was bent so the travel distance would stick about 1/4 inch from full closed. Bent it back and found it to move from full open to full closed by sucking on it. The shaft moved freely with the vacuum shutoff actuator removed. (I could not find a supplier to purchase an new shutoff actuator locally)

The car burns a lot of oil. 262,000 miles on the car. When I bought the car the turbo vacuum line was unhooked and plugged. The seller did not disclose the amount of oil it burned. It took three rebuild turbos from Pure Turbo to get it to run right. Now has a lot of power. The oil press and volume thru the turbo oil supply is so great that it would blow the turbo seal on two rebuilts. The car burned a gallon of oil every 425 miles when I purchased the car. The compression and leak-down test were good. Found someone had replace the valve stem seals with all exhaust seals. After replacing the valve seals and the turbo the car now burns a gallon of oil ever 1150 miles. In removing the intake manifold last night I see the turbo is still sending oil into the engine. Is there an oil pressure regulator valve that limits volume and pressure to the turbo? Thanks. Dean |

|

#13

|

||||

|

||||

|

There is a relief valve in the oil pump IIRC, normally they will peg the needle at 3+Bar above ~1500rpm and drop to 1.5Bar-2Bar at idle. If yours is always pegged, likely the oil pressure sensor or wire is suspect, these cars won't peg the gauge hot and idling.

For oil into the intake look at your breather line (from cam-cover). There is a thread here talking about failure of a PCV assembly in the cam-cover sending too much oil spray into this hose. I can't imagine oil pressure blowing turbo seals, unless the relief valve is stuck? Seems it would cause other problems also. With the vacuum-actuated wastegate in the car I don't believe that you can get away with plugging the EGR (without losing boost), maybe re-directing the breather temporarily would be okay though. If you have oil in the intake but can't verify it is the entire oil consumption problem, there is also a problem with the head gasket #1 cylinder to oil gallery (forward of #1) failing. There were some changes through the years to correct this but I do not know the years. There was also the "rod bender" reputation of the 3.5s, not sure that the '93-up has this concern and you have checked compression & leakdown, so unlikely you have a bent rod and seriously oval/worn cylinder.

__________________

Gone to the dark side - Jeff |

|

#14

|

|||

|

|||

|

Thanks, Jeff. The car need to go to someone who enjoys working on German diesel cars. If I can put 20K more miles on the car it doesn't owe me anything. Having the engine stop working is great.

Have talked about the bend rod with a few fellows. I put the breather tube from the valve cover into a plastic bag to see how much oil was coming out on blow-by. Ran it hard for a mile or two and there was very little oil in the bag. I wired the wastegate closed as it had no boost. It has good power now. Just know not to over boost the engine |

|

#15

|

||||

|

||||

|

You can also run vacuum directly to the wastegate to keep it closed, or get creative with an overboost switch and switchover valve to cut boost above ~1bar, or install a pressure-wastegate, several options.

__________________

Gone to the dark side - Jeff |

|

| Bookmarks |

|

|