|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Ebay "Master" Ball Joint Kit for MB

I bought one... Specifically this one:

It states: Quote:

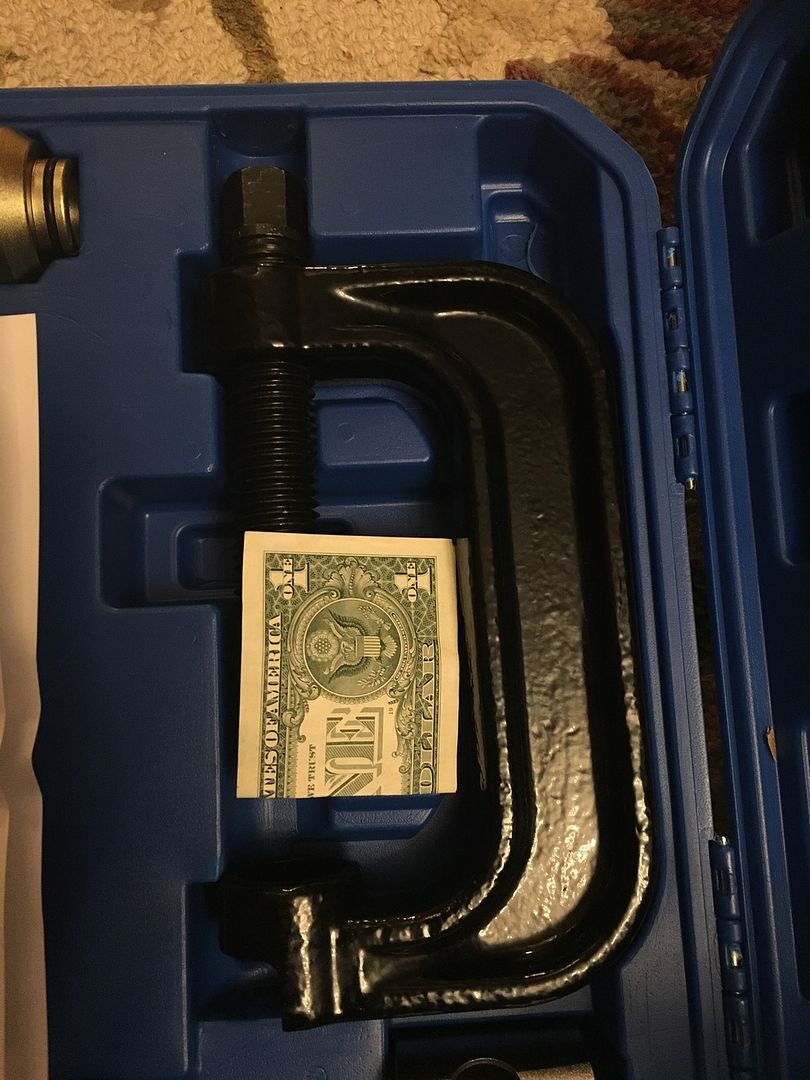

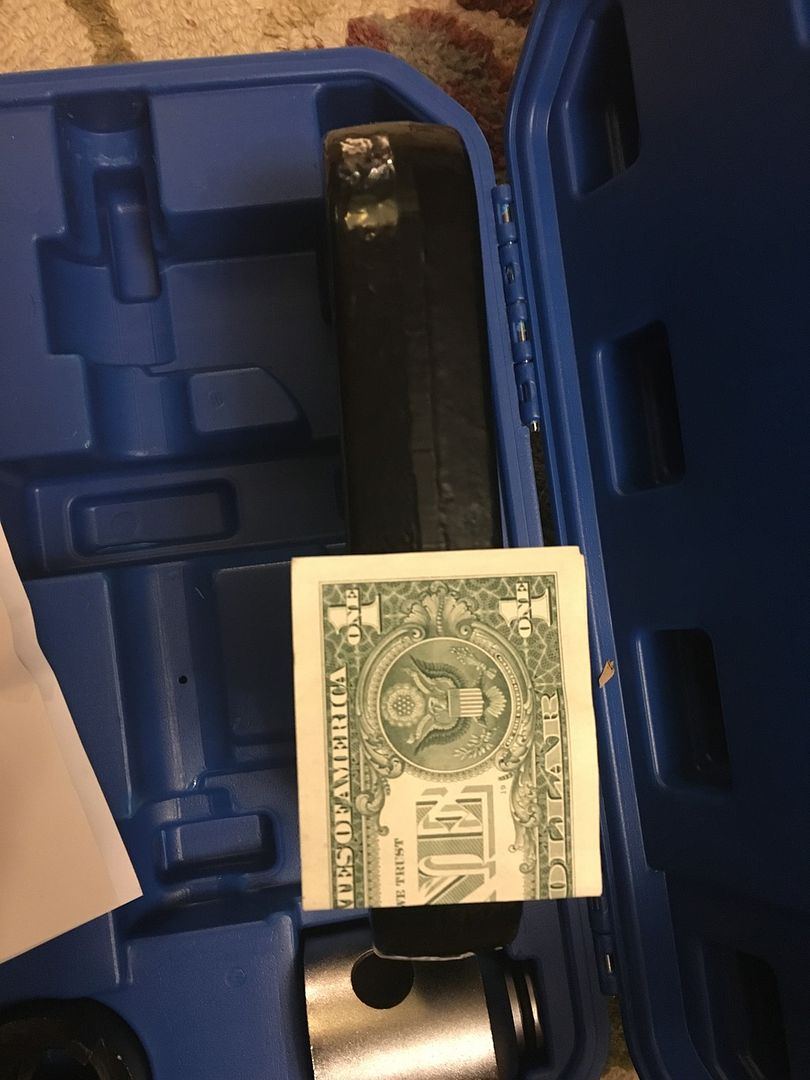

I also bought the first half of the suspension parts to refurbish my 82 300CD:  So I immediately took out a Lemfoerder ball joint (the boot wasnt clear to my surprise), and saw how it fit.  I snapped a few pictures. Reality is that I wont get around to doing this until January at best... Just too busy with so many things, and work. Its a very big, thick and heavy forged clamp. The Ebay pic doesnt really do it justice...   I found the one adapter that fit the closest... But the thing is, I have no idea what a good fit is... How much of the adapter should overlap the edge of the ball joint? I fear there may not be enough here...    I think my virtue of the shaft size, it would always move around in the adapter, but this is how far off it can be maximum...  I guess Ill only know by trying... When the time comes...

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

#2

|

||||

|

||||

|

That's certainly compelling. Is there anything special about the end that goes in the clamp? In other words, would it be hard to come up with a piece of pipe or a socket that would fit the ball joint and make it work with the clamp?

-Rog |

|

#3

|

||||

|

||||

|

The piece that goes over the ball joint has a set top diameter and an o ring in a notch to ensure a friction fit.

The real question is if the adapter is ever so slightly too large. I'd think the fix would be a fender washer ground out, with some feature on the outside to prevent slippage.

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

#4

|

||||

|

||||

|

Looking at that G-Clamp.....

I seriously doubt it would press in an MB Bottom-Ball-Joint.... They need around 4 tons pressure to get 'em in, Ive done a few and always needed proper hydraulic press with the MB tool to do 'em properly, The gauge on the press reads between 3-5 tons while the joint is actually moving into the socket....!

__________________

http://i190.photobucket.com/albums/z...0TDnoplate.jpg Alastair AKA H.C.II South Wales, U.K. based member W123, 1985 300TD Wagon, 256K, -Most recent M.B. purchase, Cost-a-plenty, Gulps BioDiesel extravagantly, and I love it like an old dog.  W114, 1975 280E Custard Yellow, -Great above decks  needs chassis welding--Really will do it this year.... needs chassis welding--Really will do it this year....

|

|

#5

|

||||

|

||||

|

Rollguy made something similar and older poster Dormisson

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#6

|

||||

|

||||

|

Quote:

It is sad that lemfoerder has replaced the Plastic Boots with Rubber ones.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#7

|

||||

|

||||

|

Quote:

Time will tell. This is designed to press MB ball joints. The clamp is far thicker and heavier than I'd have thought. If a spring compressor can clamp thousands of pounds of force with a similar headed rod, I'm failing to see why this couldn't. Especially since others have done so with the HF/Autozone kit. I'd like to compare the clamp to this one. But I took the risk on this to see if the adapters fit. One is close. If it doesn't work, it wasn't that much money, and I'll still have a tool likely useful for other stuff in the future.

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

#8

|

||||

|

||||

|

Quote:

Sorry, that matters why? Is there an established fact that plastic boots last longer than rubber? I get maybe the poly ones that some folks have been scoping out, but the ones Lemfoerder used?

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

#9

|

||||

|

||||

|

Plastic boots? Isn't plastic too rigid for ball joint boots?

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#10

|

|||

|

|||

|

I bought the HF one after using the Autozone free rental one and looked like from the same factory. It looks a bit more rugged than your clamp, but I still saw the body deflecting so much I thought it might crack. Next time, I'll use Rollguy's trick of tightening to build tension, then hammering the end of the screw to encourage the ball joint to slide in, repeat. It also helps to heat the spindle w/ a propane torch to expand the hole. Don't know about your question of the spool seating on the joint, but looks like it still presses on the end so it won't splay out. I used a polyurethane boot (Energy Suspension) instead of the thinner one that came w/ the ball joint. I forgot what brand bj, but probably put in my post (see funola's "redneck removal" thread). It did measure slight larger OD than the original one, which didn't make pressing easier.

__________________

1984 & 1985 CA 300D's 1964 & 65 Mopar's - Valiant, Dart, Newport 1996 & 2002 Chrysler minivans |

|

#11

|

|||

|

|||

|

Quote:

The frame on this looks quite sturdy, with the right cups it should work. The pictures showing the joint and cup wont work, the cup is too large and will swallow the joint in it. Bigger trouble.

__________________

2012 BMW X5 (Beef + Granite suspension model) 1995 E300D - The original humming machine (consumed by Flood 2017) 2000 E320 - The evolution (consumed by flood 2017) |

|

#12

|

||||

|

||||

|

I am in for the results, be great to have another option on the market.

I own the OE tool for W126 joints (probably W116/123 also) and it makes the job a breeze. $400 well spent seeing as I have done them on five sets now.

__________________

I'm not a doctor, but I'll have a look.  '85 300SD 245k '87 300SDL 251k '90 300SEL 326k Six others from BMW, GM, and Ford. Liberty will not descend to a people; a people must raise themselves to liberty.[/IMG] |

|

#13

|

||||

|

||||

|

I have a similar MAC tool, does the job.

I have some concern also about the adapter size and small amount of contact, might be wise to insert a sleeve or otherwise prevent the balljoint slipping inside. To reduce the installation pressure, put your balljoint in the freezer the night before the work is to begin, remove when you're ready to press in place. Too cold isn't good (liquid nitrogen for example) as the boot will become hard and shatter. Freezer temp or slightly colder will significantly reduce pressure necessary to install. As far as the cast (likely not forged) press, depends on the material and process that made it. Many different castings can look the same, but the available strength can vary a great deal. Wear safety glasses, if a cast-iron clamp fails it can shatter. Better quality is likely stronger and safer, if it truly were forged it would have a more ductile failure mode. I'm not sure what the plastic vs rubber issue is, I believe that the ones I installed were a translucent material but felt very flexible like a PUR. Rubber is really plastic, and some plastics have rubber in them, black doesn't mean that there is much or any natural rubber. Usually natural rubber is not good in direct contact with petroleum products, I'm guessing this is a PUR also just black.

__________________

Gone to the dark side - Jeff |

|

| Bookmarks |

|

|