|

|

|

|

|

|

|

|

|

|

|

#31

|

|||

|

|||

|

In person, it looks like separation of oil and not a pile of material correct?

Seen it before, not cause for alarm, likely graphite from friction plates maybe some graphite from cast iron. |

|

#32

|

||||

|

||||

|

I can't think of a single part in a 722.1 that's made of cast iron - what do you mean by graphite? Do you mean very fine swarf?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#33

|

||||

|

||||

|

OK

Quote:

If this is the first time that pan has been off. This is normal wear and tear trash. Here are pictures of plugged transmission filters and serious sludge. .      .

__________________

ASE Master Mechanic https://whunter.carrd.co/ Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 2003 Volvo V70 https://www.boldegoist.com/ |

|

#34

|

|||

|

|||

|

Quote:

Graphite is a form of carbon. |

|

#35

|

|||

|

|||

|

That may be true, but per a suggestion from Stretch, I used a relatively strong flat bar magnet and moved it around the bottom of the pan. What ever is in there is non magnetic for nothing stuck to the bottom of the magnet. The pan has been cleaned out and a new filter installed. The pan has been put back on the tranny.

Last edited by steeleygreg; 02-03-2014 at 11:16 PM. |

|

#36

|

||||

|

||||

|

I''ve got a spare .1 transmission... not sure the exact number, but if you need it, I'll clean it, and get you exact info.

__________________

John HAUL AWAY, OR CRUSHED CARS!!! HELP ME keep the cars out of the crusher! A/C Thread "as I ride with my a/c on... I have fond memories of sweaty oily saturdays and spewing R12 into the air. THANKS for all you do! My drivers: 1987 190D 2.5Turbo 1987 190D 2.5Turbo 1987 190D 2.5-5SPEED!!!  1987 300TD 1987 300TD 1994GMC 2500 6.5Turbo truck... I had to put the ladder somewhere! |

|

#37

|

|||

|

|||

|

Thank John, I may have to take you up on that. A test drive will tell !

|

|

#38

|

||||

|

||||

|

Quote:

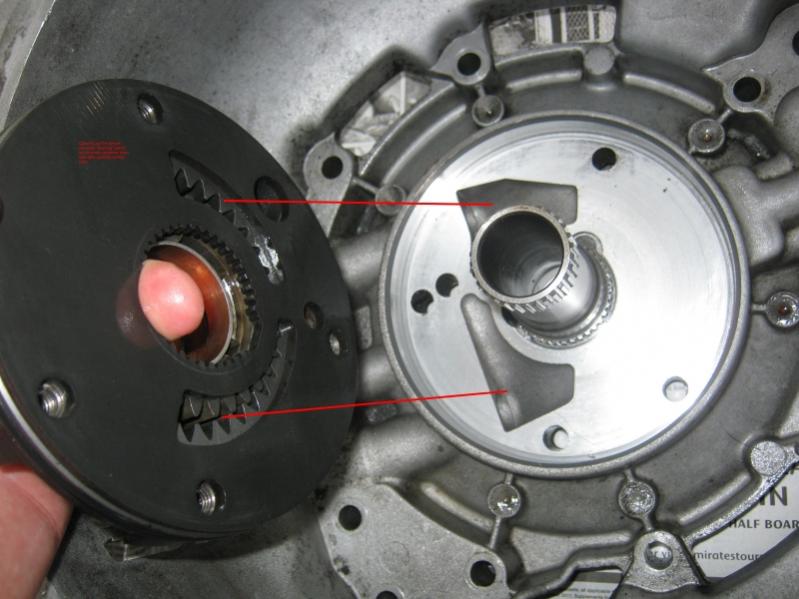

Here are pictures of the front pump     Here's a picture of a clutch plate  Used brake bands   All pictures in this thread 722.118 Automatic transmission rebuild (Monster DIY)

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#39

|

|||

|

|||

|

Due to frustration and cold weather, this job has taken a little longer than expected. The frustration was from tranny oil leaking on the floor between the pan and the transmission casing. I discovered that this is a normal occurrence for the pan with the new gasket doesn't seal correctly and takes some playing around to get it right.

When looking at the torque specifications for the filter pan bolts, their not very tight. I remembered that they where held securely and where somewhat difficult to remove. It was like someone used locktite on the threads. So I treated this as something which needed the threads cleaned so the bolts would go in smoothly and without binding. I first started with cleaning the bolts. Die required was 1.25 * 8mm. Next was to clean the threads with a tap. What was discovered was I not only removed the old thread material but also so aluminum buried in the hole and caked with oil. The bolts screwed into the holes without a problem. Last edited by steeleygreg; 03-15-2014 at 09:50 AM. |

|

#40

|

|||

|

|||

|

Ok folks I've got some good news. Results are in attached file. Don't know how to insert the image into post.

Summary is that trans, although may not be at factory spec, and I didn't expect it to be, it shift in and out of gear flawlessly, minimum shifting delay's between Neutral, drive and reverse. Still has good pickup especially in regards to transmission pressure readings. All in all I'm pleased with the results from changing the filter and fluid. Although I may have a trans which will fail in the future, at the moment I cannot tell but it seems to be responding better than when I bought the car. Attached pic's are at pressure reading in idle in park. Note: Shift delay from "N" to Rev = approx 1 sec Shift delay from "N" to Drv = approx less than 1/2 sec Car was at operating temp of 80C as shown From dead stop and pressing the pedal to the floor, pressure pegs above 10 bar, then drops to above 50 psi then to 70 as it shifts into 2nd. Same results in Reverse. With pressing pedal to floor in reverse pegged gauge above 10 bar dropping to 8.2 as speed leveled off. No notice of trans failing to shift or turn rear wheels as in test prior to changing filter. Trans fluid level on stick is at top level mark on dip stick after test was completed. Last edited by steeleygreg; 03-17-2014 at 02:11 AM. |

|

#41

|

||||

|

||||

|

Screen shot of results

Here's a screen shot of the results in your word document Greg

I love the use of two units of pressure! The idea, however, is to reproduce the situations in the FSM so you can compare your measurements with this data

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#42

|

|||

|

|||

|

Stretch, I was trying to reproduce the FSM and thought I did. Please advice if I didn't! The transmission according to the VIN is a 722.117. Using your chart for reference, the modulating pressure should be 2.8 at 40. Mine is 2.6. Wrking pressure should be 5.2, mine at 4.8 bar. The results in my chart where at driving at 40 mph which according to the FSM reading should be done at that speed. If I'm not mistaken, I still have some life left in this transmission, but there are signs of wear as expected.

Last edited by steeleygreg; 03-17-2014 at 08:40 AM. |

|

#43

|

||||

|

||||

|

Quote:

Tests are With "D" selected 1) Measure modulation pressure => at stand still 2) Measure working pressure => at stand still 3) Measure modulation pressure => at 65km/h 4) Measure working pressure => at 65km/h With "R" selected 5) Measure working pressure => at stand still If the working pressure at a standstill is too low then it might be worthwhile considering a new front pump (as discussed before) Note temperature readings are probably best made on the bottom of the transmission oil pan.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#44

|

|||

|

|||

|

I agree with the pump replacement. Converting to FSM display of data as follows:

With "D" selected 1) Measure modulation pressure => at stand still ------ 1.3 2) Measure working pressure => at stand still ---------6.7 3) Measure modulation pressure => at 65km/h ---------2.6 4) Measure working pressure => at 65km/h ------------4.8 With "R" selected 5) Measure working pressure => at stand still ---------- 8.2 units are in bar |

|

#45

|

||||

|

||||

|

Well Greg the only really big difference is the working pressure with reverse selected. That's my biggest concern.

With "D" selected 1) Measure modulation pressure => at stand still ------ 1.3 => should be 4.4 +/- 0.2 2) Measure working pressure => at stand still ---------6.7 => should be 7.2 +/- 0.4 (used value from 1979) 3) Measure modulation pressure => at 65km/h ---------2.6 => should be 2.8 4) Measure working pressure => at 65km/h ------------4.8 => should be 5.2 +/- 0.2 (alternatively 4.9 +/- 0.2 for 1979) With "R" selected 5) Measure working pressure => at stand still ---------- 8.2 => should be higher than 18 (or 16 for 1979) The modulation pressure is a bit low at standstill. But the working pressure is kind of OK. I reckon it is worthwhile driving the car for a bit and after a while perhaps doing another oil and filter change to see if you get any improvement. I wouldn't mess with the modulation pressure just yet. The improvement in the measurements after a fluid and filter change are really promising. Drive the car - but don't let the transmission slam into gear. Check your fluid level again

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

| Bookmarks |

|

|