|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

722.118 Automatic transmission rebuild (Monster DIY)

Here's a DIY to encourage you all to take a closer look at your transmissions if you get a problem, rather than just swapping for another or buying reconditioned.

When I announced here on this forum (!) that I was about to rebuild my 722.118 I was basically told not to be silly and that I should be really scared. I was told under no circumstances to take the valve body to bits... Having done it I don't know why: under perfect conditions I estimate this job would be achievable for a competent DIY mechanic in a weekend, perhaps a long weekend. Unfortunately, as has been the way with this car of mine, the conditions were less than what I consider to be perfect so it took about 4 months to get my ducks lined up. The biggest problem I had was spares availability. It has taken me nearly six times longer to write this up than it did to actually do the job. Please note this DIY does NOT detail the process of adjusting the transmission when it has been fitted to the car. This DIY only covers taking it to bits and putting it back together again. I expect, when I get to it, that the adjustment process will be a challenge. That might be a future DIY but there are already some good threads on the subject (http://www.peachparts.com/Wikka/Trans722VacMod and a great compilation from whunter here Transmission:). There is also a load of information on Benz World (http://www.benzworld.org/forums/w123-e-ce-d-cd-td/1597891-diy-w123-transmission-diagnose-adjustment-722-a.html). I could not have done this job so quickly (!) without the help of rs899 – thanks for all your help and encouragement.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! Last edited by Stretch; 09-14-2011 at 04:10 AM. Reason: Finished! Removed all messages that the pictures weren't uploaded yet |

|

#2

|

||||

|

||||

|

Some information about automatic transmissions and the 722.1

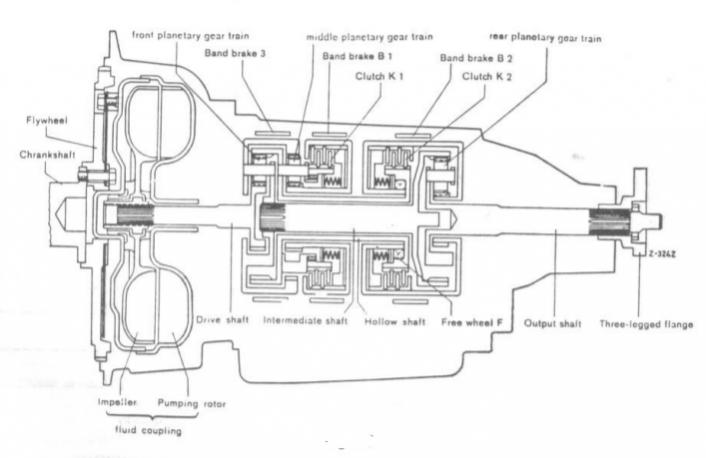

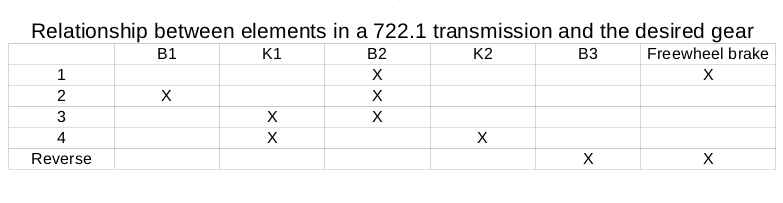

Automatic gearboxes such as the 722.1 work by using hydraulic pressure to apply brakes or clutches to stop particular parts of a sun and planet gear system from turning. The 722.1 transmission has three sun and planet gear systems. (To read more general information about automatic gear boxes and sun and planet systems have a look at these links http://en.wikipedia.org/wiki/Automatic_transmission and http://en.wikipedia.org/wiki/Sun_and_planet_gear)

Here's a schematic of the 722.1 transmission  And here's a summary of the relationship between each element in the gear box and the desired gear.  I hope this will help with the many “is it my B2 piston” threads. Here's a picture showing some names of the parts of the transmission.  You can find a nice exploded parts diagram of the 722.1 transmission here (http://www.ganzeboom.net/images1/ganzeboom/parts/Mercedes/722.0,%20722.1,%20722.2.pdf). I recommend you down load and print this pdf out before going any further! At this stage I don't fully understand how a 722.1 transmission works. I can see how in principle it should,but there are certain parts such as the ident piston in the "tail cone" section that leave me thinking what the %^&^*& is that for? If we get a long cold winter like we did last year I plan to work out exactly how the 722.1 (and perhaps also the 722.3) transmissions work. But that will be the subject of another thread.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! Last edited by Stretch; 09-12-2011 at 04:09 PM. |

|

#3

|

||||

|

||||

|

Some information about the 722.118 transmission

Here's all the information that I'm sure about regarding the different configurations of the 722.118 transmissions. If anyone knows better please post a reply / PM / email me with your information. I need some help with this.

This particular transmission is only used in diesel engined (Mercedes) cars manufactured between about 1977(?) and 1983. Prior to about 1980 these transmissions have a non-vacuum adjusting mechanism and a solid linkage (so not a Bowden cable which came later) that is connected to the throttle linkage. 79 300D upshifting problem After about 1980 changes were made to the shifting mechanism. I think the valve body was revised. What I know for sure is that the solid linkage to the throttle linkage was removed and a vacuum dash pot was fitted to the familiar rear position of the transmission just like the other 722.1 transmissions. http://www.benzworld.org/forums/w123-e-ce-d-cd-td/1597891-diy-w123-transmission-diagnose-adjustment-722-a.html If you are looking for shift point data for the 722.118 please take a look at the link on Benz World above, or on this thread Has anyone got 722.XXX diesel engined transmission shift point data? where I copied a summary of the same information.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! Last edited by Stretch; 09-09-2011 at 01:27 PM. |

|

#4

|

||||

|

||||

|

Tightening torques

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! Last edited by Stretch; 09-09-2011 at 06:18 AM. |

|

#5

|

||||

|

||||

|

Preparation

Drain the oil from the torque converter and the transmission and remove it from the car if you haven't already done so.

Remove the torque converter from the front of the transmission – there should be a little plastic plug that needs to be pulled out of the casing and then you can just pull the torque converter off – cover it up and store it somewhere safe. If the torque converter is stuck on and won't come off, you'll find lots of threads on this subject on the forum. Two tabs on the torque converter slot into the primary pump as shown in the pictures below...   ...apparently these tabs sometimes snap off. This weak point on the 722.1 was improved considerably on the 722.3 transmissions. (See post #43 by rs899 => 722.118 Automatic transmission rebuild (Monster DIY)) Clean the outside of the transmission as best you can with your favourite engine degreaser.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! Last edited by Stretch; 09-11-2011 at 02:34 PM. Reason: Added information about the torque converter connection to primary pump |

|

#6

|

||||

|

||||

|

Tools and stuff that you'll need (in no particular order)

30mm deep 12 point socket for undoing / doing up the output shaft nut with newer 12 point nut

Glossy magazine covers (to fit clutch seals) Bits of stiff but thin plastic – yoghurt pots are ideal Vernier calliper Depth vernier calliper A large woodworking clamp wide enough to bridge the width of the transmission and a bit more Heavy duty engine degreaser Brake cleaner for cleaning – lots of it. Fresh ATF Lots of bags to keep parts clean A large 3mm thick dzus screw driver or a bit of modified flat bar to remove the secondary pump A small seal tool to fit seals A larger seal removal tool Circlip pliers Some wood to make up a jig to take the K1 return piston to bits and put it back together again A source of compressed air so that you can actuate the brake band pistons and thus measure brake band clearance

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! Last edited by Stretch; 09-09-2011 at 06:19 AM. |

|

#7

|

|||

|

|||

|

This is great even without the pictures. I hope it keeps many classic MBs on the road that would have otherwise turned into Chinese crap ( that we don't need anyway)

__________________

80 300SD (129k mi) 82 240D stick (193k mi)77 240D auto - stick to be (153k mi) 85 380SL (145k mi) 89 BMW 535i 82 Diesel Rabbit Pickup (374k mi) 91 Jetta IDI Diesel (155k mi) 81 VW Rabbit Convertible Diesel 70 Triumph Spitfire Mk III (63kmi)66 Triumph TR4a IRS (90k mi)67 Ford F-100 (??) |

|

#8

|

||||

|

||||

|

This must be up there with the best trans write ups on PP !!

A definite for a wikki I think.

__________________

Grumpy Old Diesel Owners Club group I no longer question authority, I annoy authority. More effect, less effort....  1967 230-6 auto parts car. rust bucket. 1980 300D now parts car 800k miles 1984 300D 500k miles  1987 250td 160k miles English import  2001 jeep turbo diesel 130k miles  1998 jeep tdi ~ followed me home. Needs a turbo. 1968 Ford F750 truck. 6-354 diesel conversion. Other toys ~J.D.,Cat & GM ~ mainly earth moving |

|

#9

|

||||

|

||||

|

yeah, me and webmaster are CHOMPING at the bit to upload this to the wikki when it's finished!

__________________

John HAUL AWAY, OR CRUSHED CARS!!! HELP ME keep the cars out of the crusher! A/C Thread "as I ride with my a/c on... I have fond memories of sweaty oily saturdays and spewing R12 into the air. THANKS for all you do! My drivers: 1987 190D 2.5Turbo 1987 560SL convertible 1987 190D 2.5-5SPEED!!!  1987 300TD 2005 Dodge Sprinter 2500 158"WB 1994GMC 2500 6.5Turbo truck... I had to put the ladder somewhere! |

|

#10

|

|||

|

|||

|

I've got a wee gripe. A bit hard to tell with the lack of pictures, but can we see the torque converter and the mating pump gear? It would be useful when you pick through the 722.3 to illustrate and compare the two assemblies to see how MB tried to fix the earlier weak 722.1 torque converter by making the ears wider ( and making the driven tabs smaller in the pump).

This is a common failure mode with these trannies as well as the reverse band adjustment backing out. Just think those common issues need some discussion....  Rick

__________________

80 300SD (129k mi) 82 240D stick (193k mi)77 240D auto - stick to be (153k mi) 85 380SL (145k mi) 89 BMW 535i 82 Diesel Rabbit Pickup (374k mi) 91 Jetta IDI Diesel (155k mi) 81 VW Rabbit Convertible Diesel 70 Triumph Spitfire Mk III (63kmi)66 Triumph TR4a IRS (90k mi)67 Ford F-100 (??) |

|

#11

|

||||

|

||||

|

Quote:

I've got some pictures and a bit of text in post #5 722.118 Automatic transmission rebuild (Monster DIY) Is there anything else I should add?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#12

|

||||

|

||||

|

Take all the time you need with the pics! You sir, are the man!

__________________

'82 300SD - Somewhere over 220k - Becoming reliable... |

|

#13

|

||||

|

||||

|

Thanks to everyone for the encouragement. I'm sorry it has taken so long to upload the photographs. I had a bit of a computer crisis to deal with too... thank goodness for software like photorec that has helped me save a few missing files...

I've got about 4 more pictures to find then I'm done. Has anyone got any more comments with regard to stuff that should be included? I've read this DIY so many times now I can't see the wood for the trees - and there any silly mistakes that you can see? Any help will be appreciated.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#14

|

|||

|

|||

|

Quote:

I am happy with the torque converter/pump illustrations. The reverse (B3) is also well done ( page 3, #32 and #37) although I don't think you specifically mention that it has a habit of backing out and making one think one's transmission is in need of serious repair when it isn't. As for how the adjuster looks - I think they all have that look. I think I read somewhere that they snapped off the adjusting lugs at the factory or some such thing.

__________________

80 300SD (129k mi) 82 240D stick (193k mi)77 240D auto - stick to be (153k mi) 85 380SL (145k mi) 89 BMW 535i 82 Diesel Rabbit Pickup (374k mi) 91 Jetta IDI Diesel (155k mi) 81 VW Rabbit Convertible Diesel 70 Triumph Spitfire Mk III (63kmi)66 Triumph TR4a IRS (90k mi)67 Ford F-100 (??) Last edited by rs899; 09-12-2011 at 07:55 AM. |

|

#15

|

||||

|

||||

|

Quote:

It isn't my intention to baffle anyone - I'm trying to explain what I found and how I "fixed" it. I get the impression from what you say that what I've written isn't particularly clear or particularly inspiring - bugger. As usual too much information?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

| Bookmarks |

|

|