|

|

|

|

|

|

|

|

|

|

|

#16

|

||||

|

||||

|

Quote:

(Not that I don't understand - but it would be nice to make it clear for everyone - just in case)

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#17

|

||||

|

||||

|

I usually remove the bracket, engine mount arm (usually end up replacing motor mount also) and little engine shock. I also jack the motor up. In the end its more work but installing them is as easy as setting them in their place instead of puzzling them in

__________________

|

|

#18

|

|||

|

|||

|

Pics

$60 total, P&L, from hose company.

|

|

#19

|

||||

|

||||

|

Nice one - thanks for posting the pictures:-

I'll make 'em BIG if you don't mind   How do they look when fitted in place? When you fitted them did you get the feeling they were in there "solid" enough? I've got the impression that there is a bit of pressure from the flexible hoses pushing back onto the solid ones... ...I mean the nightmare situation would be that the new joint in the lines kinks and they leak. Sorry to sound so paranoid! (I'm still a fan of the modification though)

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! Last edited by whunter; 11-21-2011 at 02:37 PM. Reason: attached pictures |

|

#20

|

||||

|

||||

|

Quote:

I have read that some of the Compression Collors for hydraulic use bite into the metal when the Nuts are tightened. So I guess that would secure them well enough. Other then it looks ugly I only replaced the Hose part and installed the new hose with double Hose Clamps. 3 years plus and with the exception that one seeped a little and needed the Clamps tightened I have had no issues. It was a cheap fix and I did not need a Hydraulic Shop.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#21

|

|||

|

|||

|

Quote:

|

|

#22

|

|||

|

|||

|

Yep think that's what I'm going to do!

|

|

#23

|

|||

|

|||

|

Good idea, that would be the simplest!

|

|

#24

|

||||

|

||||

|

I don't know the Details but when ForcedInduction replaced the Oil Cooler Hoses on his 300D turbodiesel He replaced them with Stock Hoses but from an earlier Model. And, the earlier Model ones are easier to install because they; if I remember correctly run over the Top of the Motor Mount instead of under it.

I don't have a link to that thread I read that in so I can't direct anyone to exactly what He wrote on that.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#25

|

||||

|

||||

|

Quote:

(Probably not - because you are most likely sweating ans swearing at the oil cooler line rather than messing about with cameras - but it is worth asking) I think I'm going to have to buy a turbo engined w123 with ac to check this out for myself! The ac compressor is lower than the oil cooler lines right?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#26

|

||||

|

||||

|

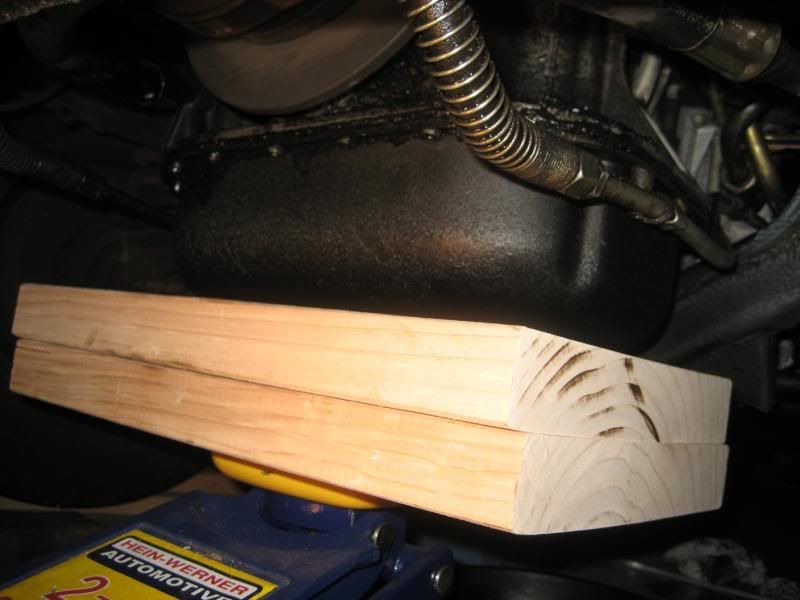

These are indeed a PITA. You guys only unbolted the drivers motor mount\shock and had enough clearance? Where were you jacking the engine? Oil pan with block of wood? Have the middle mount bracket, oil cooler, and above all free and open to suggestions to get this done..

|

|

#27

|

||||

|

||||

|

Quote:

Engine shocks and mounts Some pictures of when I pulled the shocks and mounts to do the cooler lines. A few others:     I thought I had written a DIY for oil cooler lines with all the pics, but cant seem to find it...

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

#28

|

||||

|

||||

|

Appreciated. Removed the passenger engine mount, took my purse off, and jacked it up some more. One of my least favorite repairs to date.

|

|

#29

|

||||

|

||||

|

Quote:

(Did you take any pictures?)

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#30

|

|||

|

|||

|

Thanks for all this helpful information

I have for the past 60 000 miles driven my 79 W123 non-turbo with a home-made job in which I fitted heavier flex hoses and double clamped them with the sturdiest clamps I could buy. This way I did not have to undo anything. But I now have a pair of lines from a turbo SD that are in good shape, and I want to redo the job. Does anyone know if the turbo lines, though a bit fatter, can be fitted easily onto a non-turbo? Both vehicles have the GM style ac compressor. |

|

| Bookmarks |

|

|