|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

Oil cooler lines / compression fittings?

Time to replace the oil cooler lines and wanted a cheaper fix.

Has anyone tried to cut hose portion off and install a compression fitting on the hard tubing then install a instalock hose.(rated at 300 psi)? What size is the hard line? |

|

#2

|

||||

|

||||

|

Quote:

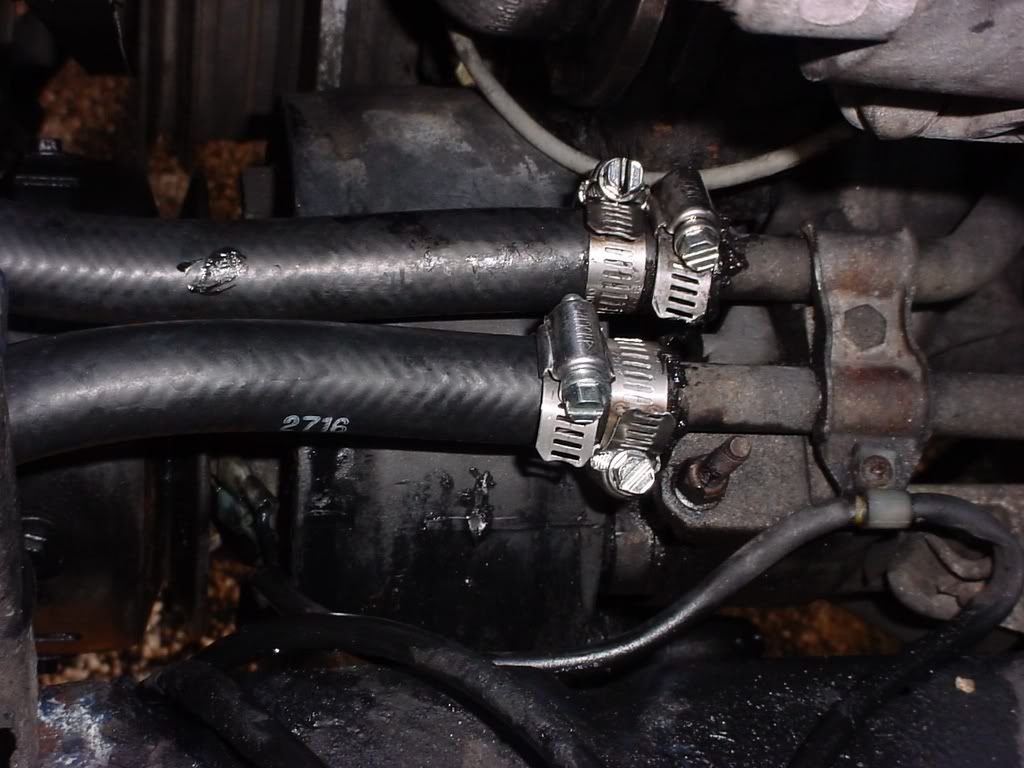

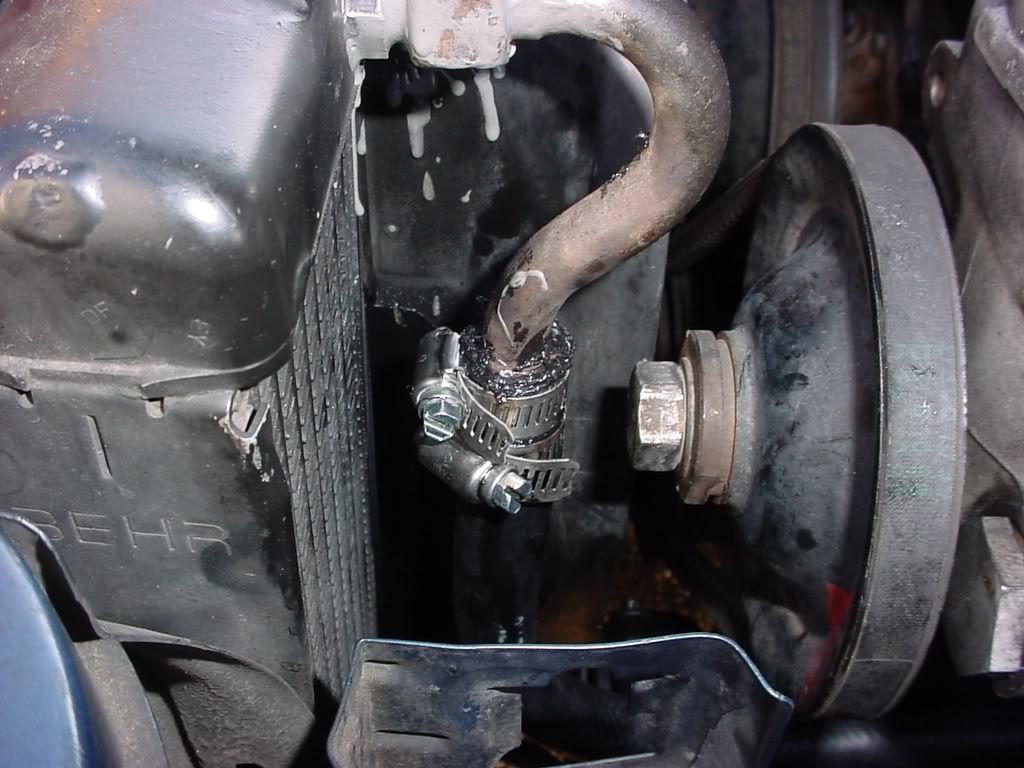

Here is the thread on what I did and has been on my car since then with no leaks of other problems. As talked about in the thread 1/2 inch Hose would not fit over the Hose Barbs and 5/8 Hose fits loosely (it would be best to use metric sized hose to use the origional barbs). I used 5/8 Good Year Insta Grip. The Max Oil Pressure is around 110 psi so 300 psi hose is over kill. The next problem was the Insta Grip hose is kind of stiff as far a compression goes and I put 2 regular American mad hose clamps on each hose end to be sure it sealed. However, "T" Bolt type clamps would have been better but at the time I had no source to buy them from. [Since then I found them at a local Truck supply place but did not buy any as my hoses are not leaking and I do not want to mess with them; cost was around $7 per clamp.] Below is my original Thread and some pics. If you have room to grind or file the collars off you do not need to remove the Fittings from the Oil Cooler or the Oil Filter Housing. Cheap oil cooler hose replacement.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 01-20-2009 at 07:15 PM. |

|

#3

|

||||

|

||||

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#4

|

||||

|

||||

|

I only cried once when I bought my oil lines.

__________________

1984 123.193 372,xxx miles, room for Seven. 1999 Dodge Durango Cummins 4BTAA 47RE 5k lb 4x4 getting 25+mpgs, room for Seven. |

|

#5

|

||||

|

||||

|

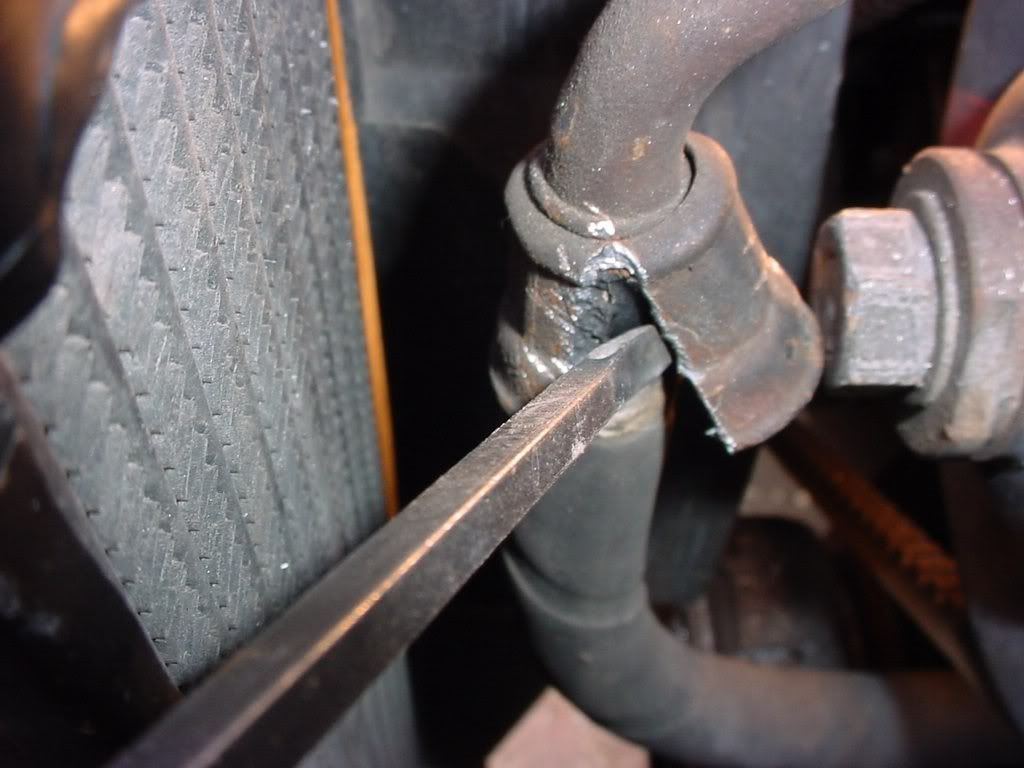

If you look at my very last picture you will notice a lot of JB Weld sealing the upper Oil Cooler Fitting.

This is because when I backed off the nut it stripped off several threads on the Oil Cooler Nipple. I never tried to remove the lower Connector. Would it have also stripped? At that time I did not know there was a good repair for stripped threads on an oil cooler. Also it was the only vehicle I had running at the time and I needed to get it going the same day. While the grinding with the Dremel type tool and the Rotary File was slightly difficult due to cramped space. I think the labor involved compares favorably with the labor it takes to remove the and replace the regular hoses. The hose/clamps looks ugly but is way cheaper than the Real Hoses and less risky as far as damaging the Oil Cooler. Grinding of the crimped Collars means you avoid having to unscrew the Connector Nuts and will not damage your Oil Cooler and it takes way less skill to grind off the crimped Collars than it does to do the Oil Cooler Repair if you destroy the threads. I have plenty of hose left over if it needs changing again and the next time it will be way easier. What I did was no different than people who add on an Oil Cooler to other vehicles or equipment. It is most often done with slip fit hose; at least that is what the kits come with.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 01-21-2009 at 12:25 AM. |

|

#6

|

|||

|

|||

|

Hello All,

This topic makes the rounds every month or so. The hoses start to leak after 2 decades and need replacement. Follow Diesel911's pictorial essay and you will fix the problem completely. I bought hydraulic hose from professionals and 4 clamps. It is a little crowded in there but what job on a Mercedes isn't tight? There was a little anxiety getting the new hose to bend without kinking. You need to have the new hose the proper length. The major reason to grind and not replace is; I can so no possible way of unscrewing those hose ends out of the oil cooler without stripping the threads. Years of heat have welded the hose fittings and cooler together. If the cooler gets stripped you have a real mess on your hands. I don't think I properly thanked Diesel911 for his clever solution. Truly a triumph of pragmatism over orthodoxy. Joe Marroso |

|

#7

|

|||

|

|||

|

screwed nipples

The repair for the cooler if the threads get stripped, is a kit from the dealer called "Screwed Nipples"

www.peachparts.com/shopforum/showthread.php?t=232734 link in post #1 to pictures of fix and part#. www.peachparts.com/shopforum/showthread.php?t=104244 this the thread I first read where I learned about the nipple fix. Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works Last edited by charmalu; 01-21-2009 at 11:23 AM. |

|

#8

|

||||

|

||||

|

Quote:

Also I already had the Dremel type tool to do the grinding with. What did you use? Thanks but I only get credit for posting pics and being the Lab Rat in the experiment. In my original thread there is a bunch of pro and con arguments. In one of the Posts a Member comments on how the Slip Fit Type hose is used in commercial Boating applications and I have seen many similar uses on Big Rig Trucks and Heavy Equipment. So, it is not a new idea. However, you have to be willing to take the time to find the right components and do a good installation. However, I realize that it is also means it is not the solution for everyone.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 01-21-2009 at 01:26 PM. |

|

#9

|

|||

|

|||

|

My original post was to find out what size the hard smooth part of the line was.

I was thinking of a compression fitting similar to what is used on water line valves for toilet, sinks etc in homes. Then I wanted to install a inta lock fitting on the other end of the compression fitting. The hose clamp idea may work, but i don't think its a very "bomb proof" way to do it. |

|

#10

|

||||

|

||||

|

With the right hose clamp there's no way it'd ever have a problem.

My dad plans on doing this style repair to his lines soon on his 300SD....we're going to use top-grade hose and some ultra clamps....

__________________

-diesel is not just a fuel, its a way of life-  '15 GLK250 Bluetec 118k - mine - (OC-123,800) '17 Metris(VITO!) - 37k - wifes (OC-41k) '09 Sprinter 3500 Winnebago View - 62k (OC - 67k) '13 ML350 Bluetec - 95k - dad's (OC-98k) '01 SL500 - 103k(km) - dad's (OC-110,000km) '16 E400 4matic Sedan - 148k - Brothers (OC-155k) |

|

#11

|

||||

|

||||

|

Somebody had done a double clamp "repair" job on my SD's oil cooler lines when I got it. The car leaked a ton of oil from these lines. I replaced the lines with some from fastlane and they work great. You could also take the old hoses to a hydraulic shop and have them crimp on new hose.

__________________

1979 240D- 316K miles - VGT Turbo, Intercooler, Stick Shift, Many Other Mods - Daily Driver 1982 300SD - 232K miles - Wife's Daily Driver 1986 560SL - Wife's red speed machine |

|

#12

|

||||

|

||||

|

Quote:

Another Member had the original Tubing modified (I believe welded) to accept America Hydraulic fittings (so the hose could be screwed on) and had Steele Braided Hydraulic Hose made up for him. The result is even sturdier than the Factory Made hoses. He had some very clear pics in his threads/post. There is at least 3 Threads other than mine on modes Members have made. Keep us posted on your progress!

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#13

|

||||

|

||||

|

Please, stop posting this. Its a horrible fix to a critical component.

__________________

|

|

#14

|

|||

|

|||

|

[quote=Diesel911;2085504]What companies hose did you use (should be printed on the side of the hose) and what inside diameter hose did you use? I would still like to find some hose that fits tighter on the barbs.

Also I already had the Dremel type tool to do the grinding with. What did you use? Diesel911, I will get you the specifics tomorrow. I have some hose left over so I can reliably identify. I used a Dremel type tool from Harbor Freight. Just so everybody understands, this grinding process is not a thing of beauty. In addition, one of the hoses is so far inside the engine compartment that you have to hold the Dremel tool at the end and cautiously apply pressure. As for cutting the tube to remove the barb after grinding the hose off; I consider that a bad idea. I worked the hose over the barb and clamped it on each side of the barb. It is very secure. Joe Marroso |

|

#15

|

||||

|

||||

|

Quote:

jet4power ask for info. After that it is a freedom of choice issue. I think the main condemnation of the mode is simply how it looks; it looks very iffy. While it is clear that the mode needs tighter ID hose and T Bolt type clamps to make it better; how would the worst possible thing happen? 2 clamps hold each end of the hose on so I doubt if it is possible for the hose to slip off. The hose has a 300 psi working pressure which is more than double the actual Oil pressure so the hose it self is not going to burst. I guess it could leak under the 2 clamps but I coated the barbs with Silicone Sealant before I slid the hose over the barbs; no leaks so far.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

| Bookmarks |

|

|