|

|

|

|

|

|

|

|

|

|

|

#16

|

|||

|

|||

|

Thank you all for the responses. I'm sorry it's taken me so long to respond.

I've been working on the car some. I don't know the idle speed as there's no tach in the car and I don't have a remote one that will work on a diesel. I raised the idle some and it did help with the vibration however the vibration persists just above the maximum reasonable idle speed. I also played with the priming pump some. It looks like the seals are shot so I think it may be at least part of the issue. So... Doing research here I found Bosch part numbers for the items I need to rebuild the pump. Does anyone know a Bosch distributor near SE PA/MD? I called the dealer, they could not do anything with Bosch numbers and some of the parts on their list were discontinued. Thanks in advance, Alex |

|

#17

|

|||

|

|||

|

Harbor Freight sells a cheap remote tachometer that is wonderful for these cars. It is a little handheld unit that comes with little strips of reflective tape. Put a small piece on your crank pulley, and aim the reader at it while it's at idle. It takes a little maneuvering for it to read but it works. I think I paid 37 dollars for it.

Check out Metro Injector in Allentown, PA. They are a Bosch shop. Good guys in there, they rebuilt my injectors and supplied all the seals and the diaphragm for my injection pump. If you have part numbers they will take a credit card over the phone and ship to you. |

|

#18

|

|||

|

|||

|

76W115, thanks for the information. I gave Metro Injector a call this morning and ordered the parts.

|

|

#19

|

|||

|

|||

|

Glad to help. What parts did you order? I've been considering a lift pump rebuild in the near future.

|

|

#20

|

|||

|

|||

|

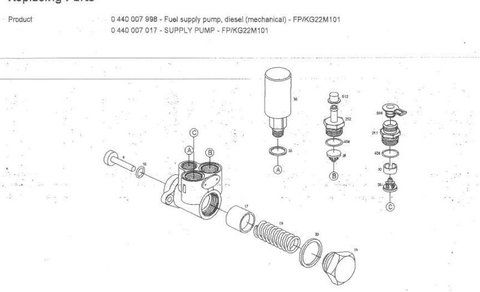

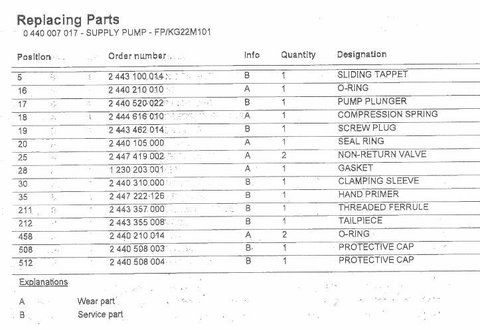

From searching the forums I found these parts lists for the euro lift pump:

The resolution is not great but you can make out the part numbers. Here is the original post with part numbers for US and Euro cars: http://www.peachparts.com/shopforum/vintage-mercedes/370355-75-240d-om616-lift-pump-part-numbers-parts.html Alex |

|

#21

|

|||

|

|||

|

I had seen that before, and wondered if that might have been what you used. Good to know the part numbers are still good. I have this wild fantasy that I will be pulling mine apart this weekend for inspection and rebuild. We'll see...

|

|

#22

|

|||

|

|||

|

I'm planning on rebuilding mine this weekend too, we'll see if that works out...I ordered all of the wear parts on the list and Metro Injector had most in stock. The rest they got in two days. I tried the MB dealership for parts too but many were NLA.

I'll report later on the rebuild. Happy Thanksgiving everyone! |

|

#23

|

|||

|

|||

|

Any news on your rebuild? I finally did mine. It seems to run a little bit better, but the biggest improvement was that I can't hear it pulsing in the exhaust any more. It used to sound like it had a burnt valve. Now it's smooth as silk.

|

|

#24

|

|||

|

|||

|

Quote:

As mentioned it is turning out that using the temperature sensing tool is quite subjective because of the slightly different reading angles etc. This said the right fuel pressure over a really substandard amount does usually make the idle better. In your case I would remove the return line from the injection pump and direct the return diesel fuel into a clear container looking for any air almost first of all. No air? Then reconnect it and close the line off to see what it does to the idle. You will not hurt anything by closing off the return line for a test. The lift pump by design just attains a certain pressure and just remains there. |

|

#25

|

|||

|

|||

|

Sorry everyone for the late response...

Got to working on the 240D again found a kinked fuel line. I replaced it and the idle has definitely improved, though still not were I'd like it to be. I rebuilt the lift pump and it did not have any noticeable effect. I still need to replace the hand primer though. 76w115, good to hear that your pump rebuild had a positive effect. Did you replace the hand priming pump too? Barry, I tried closing off the return line. Didn't seem to change anything. I think I may still have some fuel issue though... Alex |

|

#26

|

|||

|

|||

|

I had replaced it earlier, as it still had the original one and the first time I had to use it, it sprayed fuel everywhere. It's got the new style primer now.

|

|

#27

|

|||

|

|||

|

Quote:

No change at all? An indication that further investigation might find something. Might not but usually there should have been a change. The again there may be something else wrong that was masking what normally I would have expected. |

|

#28

|

|||

|

|||

|

Barry, what change would you expect to see from closing the fuel return line?

|

|

#29

|

|||

|

|||

|

If the whole fuel supply system is up to par. The fuel pressure in the base of the injection pump rises to almost the lift pumps full output pressure. This usually changes the injection pumps elements fill enough that you audiably hear the difference or change in the engine noise produced. Did you do the test again since rebuilding the lift pump?.

It will normally be different. No change may mean there is not enough pressure present to even open the relief valve. Closing the line and getting a really changed response may mean the relief overflow valve is weak. Or that the injection pump is just responding to the much greater fuel pressure. At that point or either actually a gauge measure of the pressure present in the base of the injection pump is the best way to go. As an additional test if it is pretty good pressure in the base then you close off the relief valve to see what the natural stall pressure of the lift pump is. Too close in pressure between the closed and unclosed overflow line means the engine may starve for fuel under load. Now in your case you may have another issue that makes the simple test invalid. At the same time there was an indication that I would check the fuel pressure in the base of the injection pump. It has to be somewhere near what is desired as you are working ahead of it on other problems. |

|

#30

|

||||

|

||||

|

Has the engine ever been rebuilt? The reason that I ask is that there are steps that should have been taken to balance the engine and drive train at the time of rebuild, but perhaps were omitted or not done correctly. For example, the moving parts of the engine like rods and pistons are normally balanced with respect to each other by weight, and the rotating parts (like flywheel and clutch) are balanced rotationally. Just thought I'd suggest that you consider whether you have unbalanced vibration versus uneven low-speed combustion.

Kurt

__________________

- '79 240D - engine swap complete! Engine broken in! 28-31 mpg! Lovin' the ride! - '86 190D (W201-126) - 2.5 NA engine, 5 speed, cloth interior, manual climate controls, 33-34 mpg (sold to forum member). |

|

| Bookmarks |

|

|