I just about pulled it off - hole was filled. It took several goes welding around the edge / welding over the hole to do it.

I cleaned up each attempt with ye olde angle grinder and wire brush attachment before adding a new layer - remember whilst you can get slag to spark it melts at a higher temperature than steel! You need to remove it first...

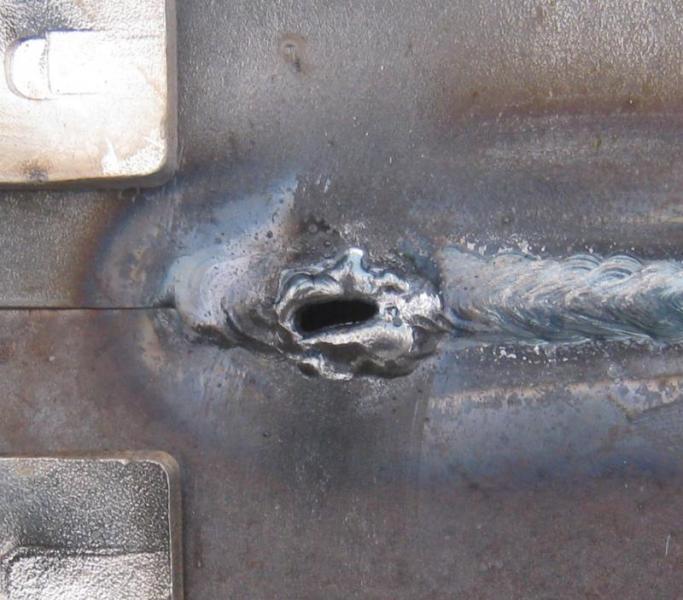

In the end I got this

Just a tiny bit of slag inclusion in the shiny bit that has been ground away (this time angle grinder and grinding disk) to make sure I've got solid metal as a joint. Not too bad - I wouldn't leave it like that on a car though: could be a stress point or a start of a crack... so I conclude I'm not good enough to weld nuclear reactors yet... or my W123.